The art of packaging

Laboratories, catering, hardware stores and many other customers are already familiar with our packaging. From small to large packaging is produced in white, transparent or in a desired color. In addition, recycled raw materials are increasingly popular for non-food applications. Besides the possibilities with the material, we can provide a bucket with various handles! Different types of lids are also available for many models.

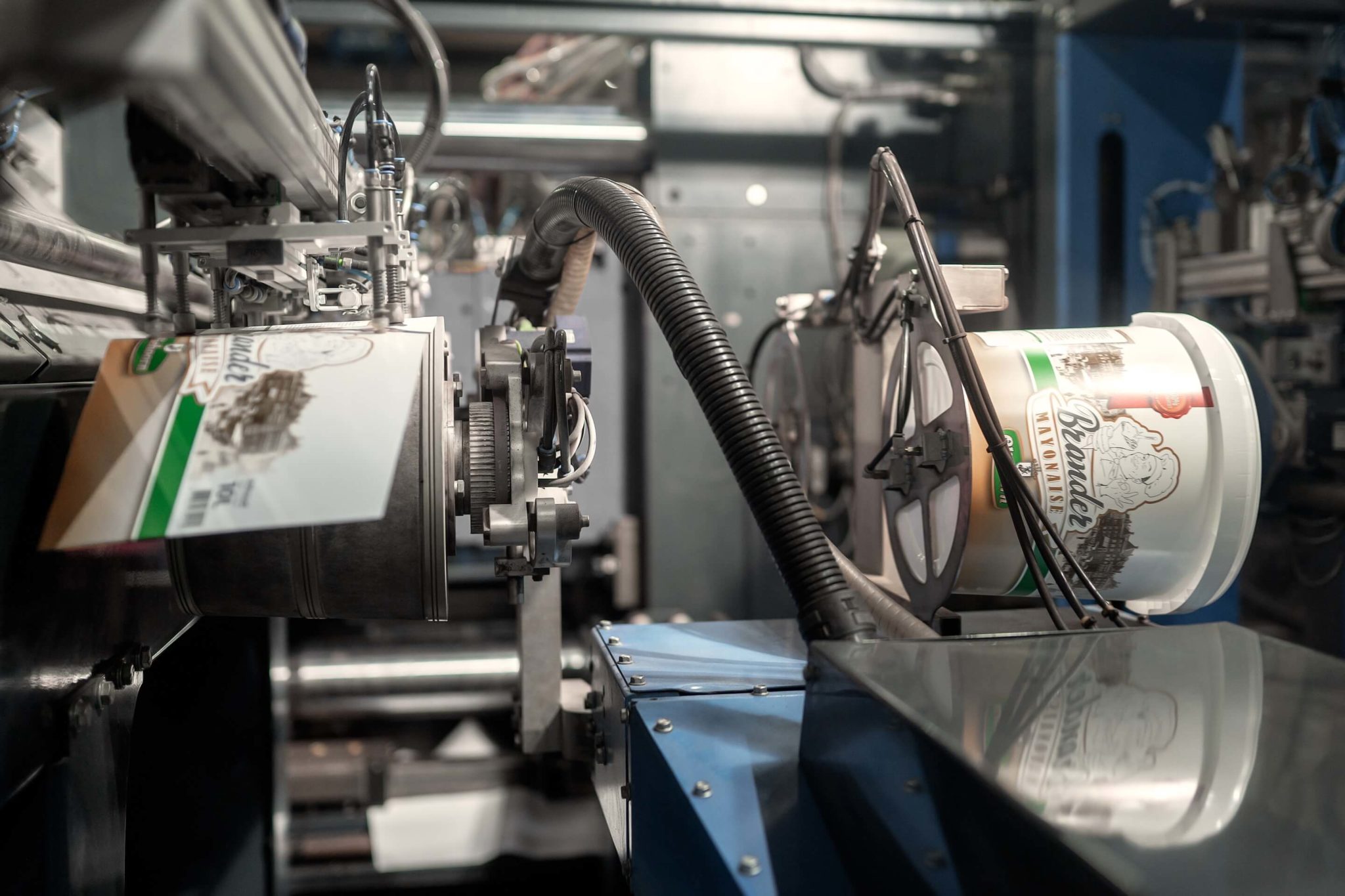

How does injection molding work?

All these different possibilities depend partly on the moulds we have made. We are happy to give you an explanation about the process of injection molding plastic products. In injection moulding, polypropylene plastic granules are heated in a tube in large machines. In this tube, a screw turns the ever-warming plastic towards the mould. Once at the front of the screw, the plastic has melted and enters the mould through a small injection point. This mould consists of two parts containing a space in which the plastic is injected. This open space is the product that is produced. With considerable force, the exact amount of plastic is quickly injected into the mould and then quickly cooled down again in the machine.

The machine then opens the two parts of the mould, after which the product is removed from the machine by a robotic arm. It is stacked on a conveyor belt and then placed on a pallet.

Adjustments to the process

At Dijkstra Plastics we have our own mould factory and we have the necessary expertise for maintenance and new developments in the field of moulds.

To adjust or even make a complete mould, there are considerable costs involved but we like to think along to see what is possible. In addition to adjustments in a mould, smaller adjustments to the process are also possible that can help to make a packaging fit you. In our wide range we have various packaging available. To give these packaging some extras, you can choose IML and/or your own color. Because there are still remnants of the previous product in the screw, a color change is not just done. When switching from recycled material to ordinary material, even the entire machine is emptied so that we can guarantee food safety! As a result, products in color or recycled material cannot be delivered directly per pallet. Because of our own efficiency and waste of plastic, we therefore plan this as well as possible. Because these steps also help to reduce plastic waste.

Costs

The cost of packaging depends on various factors. Because a mould can have several cavities for products, several packaging (or parts) can be made at the same time. In addition to the manufacturing costs, there are costs for the plastic itself. These are tracked in a global index called ICIS (Independant Commodity Intelligence Services). We use this index as the basis for our sales prices.

Examples

Links

Check out our full range here. Can’t find what you need or looking for something special? Feel free to contact us for the endless possibilities of injection moulding!

Video

BRC Packaging

BRCGS is a standard for food safety. The standard describes the hygiene and food safety requirements for food processing companies that supply directly to the retail sector. You can also think of packaging materials for foodstuffs.

FSSC 22000

The FSSC 22000 Standard has been created through Stichting Certificatie Voedselveiligheid (SCV). As a food-oriented version of the ISO 22000 Standard, this certification programme has been set up as a global guideline in food safety and quality within various industries. This standard is aimed at the entire production chain and as such, it is ideally suited for international harmonisation, partly thanks to the recognition by the GFSI. In addition to its connection with ISO 22000, the FSSC 22000 has many comparisons with the HACCP criteria, making it an attractive variant with the best of both worlds from these programmes. Thanks to the internationally accepted nature of the FSSC and the chain-wide approach within this certification programme, we recognise a strong food safety management system in this standard.